Product Details:

Payment & Shipping Terms:

|

| Flow Range: | 4-2040 M3 / H | Head Range: | 2-300m |

|---|---|---|---|

| Speed: | 2950r/min、1450r/min | Working Pressure: | Under 3.0 MPA |

| Seal Type: | Double Mechanical Seal | Temperature: | <80 Degree |

| High Light: | centrifugal chemical pump,industrial chemical pumps |

||

Semi Open and Closed Impeller Design Electric Chemical Transfer Pump Split Case Pump

Specification

| Discharge Size | Inlet Size | Capacity | Head | NPSH |

| 32mm~200mm | 50mm~250mm | 4~2600m³/h | 2~300m | 1.4m~3.5m |

Main Features

Can be used for continuous or irregular service.

Less costly, yet can handle a wider range of chemicals than any special pumps.

Choice of threaded or flanged fitting available.

Appropriate for highly corrosive liquids.

Provided range facilitate effective solutions for all process industries.

All spare parts interchangeable with most of the International brand pump.

Details

| Accessories | Character |

| Mechanical Seal | High temperature resistance, acid and alkali resistance, corrosion resistance, wear rsistance and other characterisics, especially suitable for all kinds of bad environment. |

| Impeller Ring | Professional measuring tools to closely measure the bearing joints to ensure the accuracy to international standards. |

| Motor | Less heat generation, higher operating efficiency and longer service life. No obvious vibration when carring over the flat ground. |

Pump Structure

Pump seal a variety of structural forms, the most commonly used is built-in unbalanced single-ended mechanical seal. According to the working conditions, can also use the external, unbalanced or double-sided mechanical seal. Flushing cooling method can be flushing or flushing, you can also install additional sealing device. On the suspended particles or less corrosive media, can also choose to use soft packing seal (flushing or flushing).

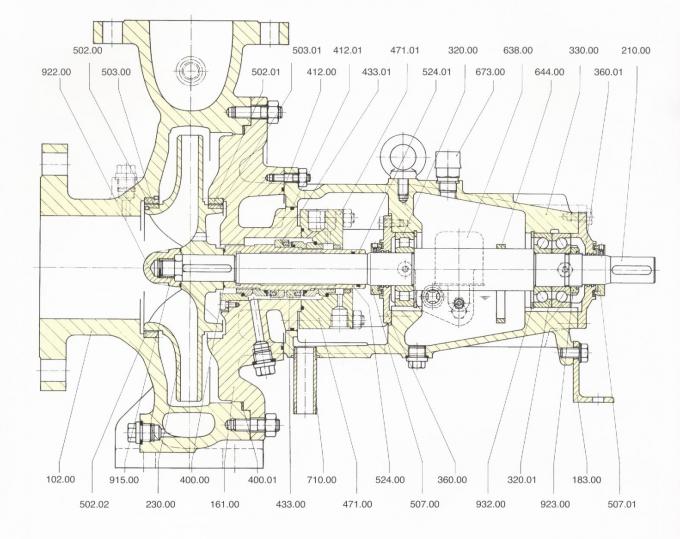

Drawings

|

102.00 |

pump body |

161.00 |

pump cover |

183.00 |

Support foot |

|

210.00 |

shaft |

230.00 |

impeller |

320.00 |

Antifriction bearing |

|

320.01 |

Antifriction bearing |

330.00 |

Bearing bracket |

360.00 |

Bearing cover |

|

360.01 |

Bearing cover |

400.00 |

Flat gasket |

400.01 |

Flat gasket |

|

412.00 |

O ring |

412.01 |

O ring |

433.00 |

Mechanical seal |

|

433.01 |

Mechanical seal |

471.00 |

Sealing cover |

471.01 |

Sealing cover |

|

502.00 |

Casing wear ring |

502.01 |

Casing wear ring |

502.02 |

Casing wear ring |

|

503.00 |

Impeller wear ring |

503.01 |

Impeller wear ring |

507.00 |

deflrctor |

|

507.01 |

deflector |

524.00 |

sleeve |

524.01 |

sleeve |

|

638.00 |

Constant-level-oiler |

644.00 |

Lubricating ring |

673.00 |

Vent filter |

|

710.00 |

pipe |

915.00 |

Threaded insert |

922.00 |

Impeller nut |

|

923.00 |

Bearing nut |

932.00 |

circlip |

Working Medium and Application

Inorganic and organic acids of various temperatures and concentrations

Alkaline solution of various temperature and concentration

Salt solution of various temperature and concentration

Various liquid petrochemical products, organic compounds, corrosive raw materials and products

Chemistry

Food processing

Paper work

Sea water station

Environmental equipment

Our Certification

Contact Person: Cecile

Tel: 0086-19180408652