Easy Maintenance Energy Efficient Single Stage Anti-Corrosive Horizontal Chemical pump

-

-

Large Image :

Easy Maintenance Energy Efficient Single Stage Anti-Corrosive Horizontal Chemical pump

|

Product Details:

| Place of Origin: |

Sichuan, China |

| Brand Name: |

Chengdu Yongyi |

| Certification: |

ISO9001 |

| Model Number: |

ZA |

Payment & Shipping Terms:

| Minimum Order Quantity: |

1 set |

| Price: |

USD 500-5000/set |

| Packaging Details: |

Free Fumigation Export Wooden Box |

| Delivery Time: |

25 working days after receiveing advance payment |

| Payment Terms: |

L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability: |

300 sets per month |

|

Detailed Product Description

| Flow Range: |

4-2040 M3 / H |

TDH: |

2-300m |

| Color: |

Customized |

Usage: |

Acid Liquid Transfer |

| Impeller: |

Open/semi-open/closed Impeller |

Frequency: |

50 - 60 Hz |

Easy Maintenance Energy Efficient Single Stage Anti-Corrosive Horizontal Chemical pump

Main Feature

ZA-series chemical process pump is single-stage horizontal radial split volute pump.The pump body is supported by foot; the impeller is single-suction radial impeller. Liquid is sucked axially and discharged radially. According to working condition, front ring, rear ring and balance pipeare used for hydraulic balance.

- Single-stage, horizontal radial split volute pump

- Foot support of high versatility

- Bearing suspension components including shaft, impeller, shaft seal and pump cover

- Easy to be disassembled.

- Packing seal and mechanical seal, and the maximum axis bounce is within 0.05mm.

- Horizontal suction and vertical discharge

- Flanges follow the GB, DIN, ANSI, HG standards.

Performance Range

| ZA-series Chemical Process Pump |

| Technical Parameter |

Medium |

| DN |

25-400mm |

- inorganic and organic acids of all temperatures and concentrations

- alkali liquor of all temperatures and concentrations

- salt solution of all temperatures and concentrations

- liquid petrochemical products, organic compound

- corrosive raw materials and products

|

| Flow Q |

<2600m3/h |

| Head H |

<250m |

| Pressure P |

<2.5MPa |

| Temperature T |

-80℃-450℃ |

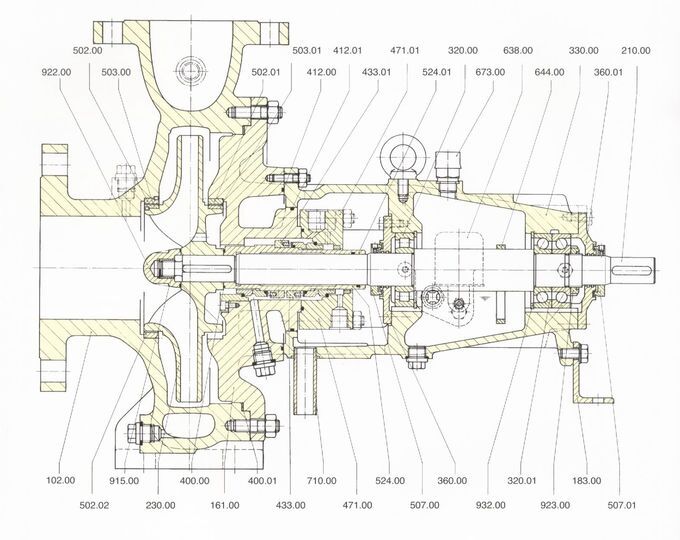

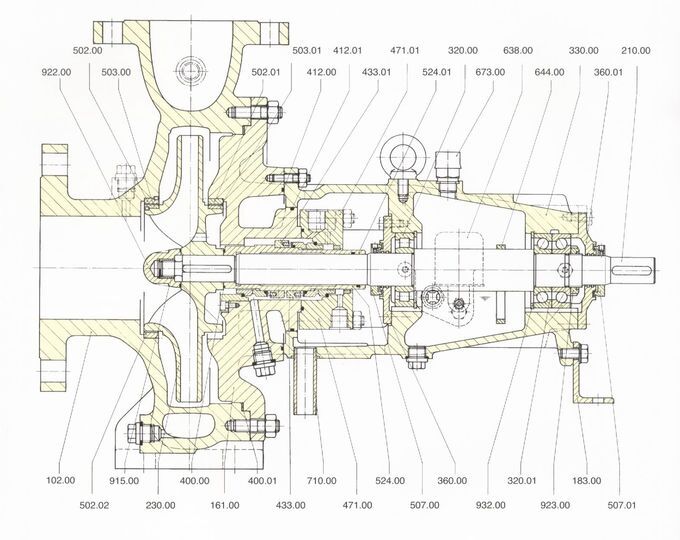

Structure

| 102.00 |

pump body |

161.00 |

pump cover |

183.00 |

Support foot |

| 210.00 |

shaft |

230.00 |

impeller |

320.00 |

Antifriction bearing |

| 320.01 |

Antifriction bearing |

330.00 |

Bearing bracket |

360.00 |

Bearing cover |

| 360.01 |

Bearing cover |

400.00 |

Flat gasket |

400.01 |

Flat gasket |

| 412.00 |

O ring |

412.01 |

O ring |

433.00 |

Mechanical seal |

| 433.01 |

Mechanical seal |

471.00 |

Sealing cover |

471.01 |

Sealing cover |

| 502.00 |

Casing wear ring |

502.01 |

Casing wear ring |

502.02 |

Casing wear ring |

| 503.00 |

Impeller wear ring |

503.01 |

Impeller wear ring |

507.00 |

deflrctor |

| 507.01 |

deflector |

524.00 |

sleeve |

524.01 |

sleeve |

| 638.00 |

Constant-level-oiler |

644.00 |

Lubricating ring |

673.00 |

Vent filter |

| 710.00 |

pipe |

915.00 |

Threaded insert |

922.00 |

Impeller nut |

| 923.00 |

Bearing nut |

932.00 |

circlip |

Advantage

- Double mechanical seal available for clogging material application, single mechanical seal and packing seal are stll avaiable.

- Can be used for continuous or irregular service.

- Less costly, yet can handle a wider range of chemicals than any special pumps.

- Choice of threaded or flanged fitting available.

Why Choose Us

- 1.Warranty Period: one year (Attention: Machine's warranty range don't include damageable Spare Parts. For other parts,providing new free parts for clients in warranty period)

- 2. Supporting for technique for pumps

- 3.Free train using machine and free repair