Product Details:

Payment & Shipping Terms:

|

| Material: | New Carbon Fiber Composite Material | Max Flow: | 400m3/h, 7m3/min |

|---|---|---|---|

| Max Head: | 50m | Power: | 160KW |

| Temperature: | -20C-105C; 68°F-302°F | Efficiency: | 17-88% |

| High Light: | corrosion resistant pumps,carbon fiber pump |

||

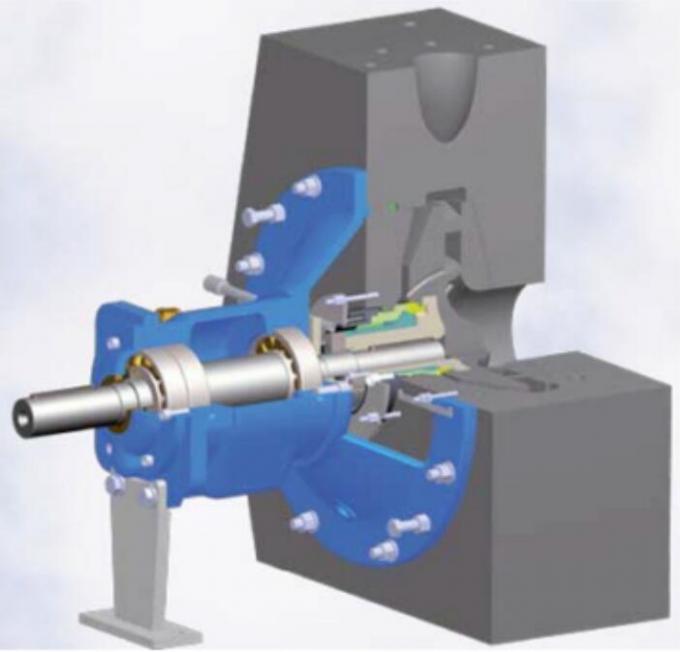

New Type Leakproof Chemical Resistant Chemical Liquid Pumps Electric Motor Driven

Product Description

The new carbon fiber composite material is our self-developed high-strength composite material, and has obtained national invention patent (patent number ZL201310597859.0, ZL201310343890.1). This material, based on carbon fiber and silicon carbide, with US imported special cross-linking agent, is made by chemically reacting at high temperature, and has extreme high corrosion resistance and wear resistance. The hardness of silicon carbide is almost as high as that of the diamond, so it has excellent wear resistance. Carbon fiber can improve the toughness of material to meet the flexural performance.

Model Description

80DCS-315:

80 --------------- Outlet diameter

315---------------- Impeller diameter

DCS ----------------- New carbon fiber composite material pump

Technical Parameter

|

Model |

Flow (m³/h) |

Head |

Rotating speed |

Highest efficiency |

NPSHr (m) |

|

50DCS-250 |

30-50 |

15-28 |

1450 |

40 |

1.4 |

|

50DCS-310 |

30-60 |

25-38 |

1450 |

45 |

1.5 |

|

50DCS-350 |

30-60 |

35-50 |

1450 |

43 |

1.8 |

|

65DCS-250 |

50-80 |

15-28 |

1450 |

48 |

1.8 |

|

65DCS-310 |

50-100 |

25-38 |

1450 |

50 |

2.2 |

|

65DCS-350 |

50-100 |

35-50 |

1450 |

55 |

2.2 |

|

80DCS-250 |

70-140 |

15-25 |

1450 |

61 |

2.5 |

|

80DCS-310 |

70-140 |

25-38 |

1450 |

62 |

2.5 |

|

80DCS-350 |

70-160 |

35-50 |

1450 |

63 |

2.8 |

|

100DCS-310 |

100-220 |

20-35 |

1450 |

57 |

2.8 |

|

100DCS-350 |

100-220 |

35-48 |

1450 |

60 |

2.8 |

|

125DCS-310 |

120-250 |

18-33 |

1450 |

62 |

3 |

|

125DCS-350 |

120-290 |

35-48 |

1450 |

62 |

3 |

|

150DCS-310 |

200-400 |

18-33 |

1450 |

64 |

3.5 |

|

150DCS-350 |

200-500 |

25-45 |

1450 |

65 |

3.5 |

Cast Process Advantage

After studied the material properties, our company has found a special manufacturing process.

Thermal curing casting: The entire manufacturing process of DCS materials is carried out under vacuum and high temperature. The combination of coupling agent, tantalum carbide and carbon fiber is perfect.

Cold-cure casting: Some pumps may have voids, and then repair materials are essential to repair it. The method is cold-cure casting, but the material properties are far less than thermal curing.

Advantage

Comparison to Other Material

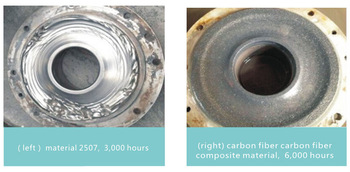

A contrast test between carbon fiber composite material and material 2507: under the same condition, medium: F, CI>800ppm, containing 12%sulfuric acid and 30%solid content, and its temperature is 90℃

1) Metal materials have relatively low corrosion resistance and wear resistance

Pump Design Feature

Contact Person: Cecile

Tel: 0086-19180408652